| SOLDER WIRE: Lead-Free |

| 275 |

Superior wetting no-clean flux-EMS, OEM and contract manufacturing, PCB assembly, energy, automotive, aerospace, medical |

| 268 |

Zero-halogen cored wire for robotic soldering -EMS, OEM and contract manufacturing, PCB assembly electronics manufacturing |

| 331 |

High activity, water-soluble for soldering difficult metals -consumer goods/appliances, electrical, industrial, military, medical, aerospace, energy, transportation |

| 48 |

Activated rosin flux developed for lead-free applications -energy, automotive, aerospace, medical, general manufacturing, electrical, industrial, fabrication |

| SOLDER WIRE: Leaded |

| 245 |

No-clean flux core choice for leaded builds -EMS, OEM and contract manufacturing, PCB assembly, energy, automotive, aerospace, medical |

| 268 |

Zero-halogen cored wire for robotic soldering -EMS, OEM and contract manufacturing, PCB assembly electronics manufacturing |

| 331 |

High activity, water-soluble for soldering difficult metals -consumer goods/appliances, electrical, industrial, military, medical, aerospace, energy, transportation |

| 44 |

Activated Rosin Flux Designed for Instant Wetting Action -energy, automotive, aerospace, medical, general manufacturing, electrical, industrial, fabrication |

| SOLDER PASTES: Lead-Free |

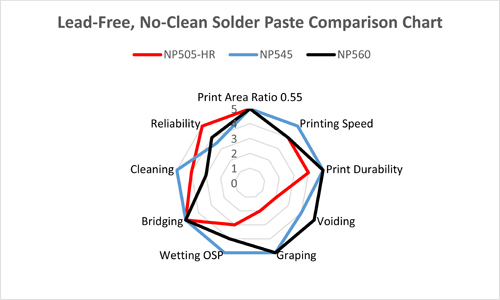

| NP545 |

Zero-halogen, no-clean paste with a wide process window ideal for low-volume/high-mix EMS, or high-volume. Best in class for paste transfer. Capable of reflowing 01005 components in air with minimal graping behavior. 12-month room temperature shelf life. |

| NP560 |

Halogen-free, no-clean, ultra-low voiding paste for bottom terminated components with the ability to achieve <5% voiding. Also available in a 100g syringe for dispensing applications. |

| NP505-HR |

Zero-halogen, no-clean paste designed specifically for high reliability applications. Consistent print performance through a wide range of print parameters, temperatures and humidity. |

| WP616 |

Zero-halogen, water-soluble paste with a stable formula providing consistent print performance over a wide humidity range. |

| NP505-LT |

Zero-halogen, no-clean low temperature paste. Sn42Bi57Ag1 alloy with liquidus of 138°C allows a peak temperature as low as 160°C. |

| R276 |

Versatile no-clean dispensable paste. |

| R500 |

Dispensable water-soluble paste with superior wetting performance. |

| NXG1 |

Versatile no-clean general purpose application paste. |

| Pb-Free Alloys |

SAC305 is the industry standard. Sn42Bi57Ag1 is a low-temperature offering. |

| SOLDER PASTES: Leaded |

| NP545 |

Zero-halogen, no-clean paste with a wide process window ideal for low-volume, high-mix EMS. Capable of reflowing 01005 components in air with minimal graping behavior. 12-month refrigerated shelf life. |

| EP256HA |

No-clean paste with high activity for difficult soldering applications. Ideal for mixed-alloy applications where lead-free BGAs are placed using leaded paste. |

| R276 |

Versatile no-clean dispensable paste. Available in both leaded and lead-free alloys. |

| HM531 |

Water-soluble paste with consistent printing characteristics and superior wetting performance. |

| R500 |

Dispensable water-soluble paste with superior wetting performance. |

| Leaded Alloys |

Sn63Pb37 is the industry standard. |

| SOLDER PREFORMS |

| Tape & Reel Preforms |

Solid solder alloy in standard, chip capacitor sizes: such as 0402, 0603, 0805, etc. to selectively increase solder volume on a SMT pad or through-hole component. Available in SAC305, Sn63Pb37, SnBiAg0.4 (low temp, lead-free) and other alloys. These are alloy only, no flux. Please reference ALPHA Tape & Reel Preform Tech Bulletin for more details. |

| Custom |

Available in Kester’s lead-free and leaded alloys in stampings (washers, discs, squares, rectangles, and custom shapes) and cutoffs (squares, rectangles and pellets) |

| Ribbon |

Available in Kester’s lead-free and leaded alloys in widths from 0.050-1.0” (1.27-25.4mm) and thicknesses from 0.005-0.060” (0.127-1.52mm) |

| SOLDER ALLOYS for WAVE & SELECTIVE SOLDERING |

| Solder Alloy Common Elements |

Sn (Tin), Ag (Silver), Cu (Copper), Pb (Lead), Bi (Bismuth), Ni (Nickel) |

| Solder Alloy Naming Conventions |

Standard Tin-Lead Alloy (63/37). The numbers such as 63/37 or 62/36/2 refer to the alloying element amounts in percentages, with Tin listed first. (63/37) is 63% Sn (Tin) and 37% Pb (Lead). SAC alloys: S= Sn (tin), A= Ag (silver), C= Cu (copper). SAC Alloys are lead-free. SAC305 = 3.0% Ag, 0.5% Cu, Balance (96.5%) Sn |

| BAR SOLDER: Lead-Free Alloy Overview |

| When the migration to lead-free solder started, the primary lead-free alloy used was SAC305. Ÿ 3% Silver in SAC-305 has several benefits: Lower melting temp, lower surface tension for excellent wetting and hole-fill, and high thermal fatigue resistance. Another alloy adopted was Kester’s K100LD. Ÿ With zero silver, it offers a significant cost advantage over SAC305. It has shiny solder joints similar to tin-lead. Without silver, it has a higher melting temp and higher surface tension resulting in lower wetting speed and wetting force. It cannot match the hole-fill performance of SAC305, especially for thicker, more thermally demanding products. It also has lower thermal fatigue resistance and will fail earlier in thermal cycling than SAC305. K100LD includes small amounts of nickel and bismuth to reduce copper dissolution, and it includes small amounts of phosphorus to help reduce dross generation. Summary: High Silver (SAC305) = Higher Cost, Better Soldering and Higher reliability. K100LD = No Silver, lower cost with trade-offs in soldering and reliability, lower dross than SAC305. |

| BAR SOLDER: Lead-Free Alloy Details |

| K100LD |

Silver-free, alloy for lower cost, low dross and low copper dissolution. Melting Point: 227°C/441°F |

| Sn96.5Ag3.0Cu0.5 |

The industry standard lead-free alloy, good mechanical strength and wetting Melting Range: 217-220°C/422-428°F |

| Sn95Ag05 |

Higher melting range alloy for better strength at higher temperatures Melting Range: 221-245°C/430-473°F |

| Sn95Sb5 |

Original lead-free high temp alloy, silver-free for lower cost, good for non-electronics applications where high strength isn’t required Melting Range: 235-240°C/450-464°F |

| Sn96.3Ag3.7 |

Eutectic tin-silver, used for higher melting point than Sn63, predates SAC305. Melting Range: 221°C/430°F |

| Sn96.5Ag3.5 |

Eutectic tin-silver, used for higher melting point than Sn63, predates SAC305 Melting Point: 221°C/430°F |

| Sn97.0Ag.2Sb0.8Cu2.0 |

Kester SAF-A-LLOY. Lead-free, higher temp alloy, silver-free for electronic/medical/lighting Melting Range: 220-234°C/428-454°F |

| Sn97Ag03 |

Higher melting range alloy for better strength at higher temperatures Melting Range: 227-300°C/441-572°F |

| Sn99 |

Pure tin for tin wash on wave pots and pre tinning components Melting Point: 232°C/450°F |

| Sn99.3Cu0.7 |

Lower-cost silver-free alloy Melting Point: 227°C/441°F |

| BAR SOLDER: Tin-Lead |

| Sn63Pb37 |

Standard leaded alloy, eutectic. Melting Point: 183°C/361°F |

| Sn60Pb40 |

Slightly lower cost leaded alloy, non-eutectic, commonly used for wire and lead tinning Melting Range: 183-190°C/361-374°F |

| FLUXES: Alcohol-Based |

| 985M |

Halogen-free, no-clean general-purpose liquid flux ideal for wave or tinning. |

| NF372-TB |

High reliability, zero-halogen, no-clean wave flux designed for thick board applications. Can be used in selective soldering applications when a dropjet fluxer is not available. |

| SELECT-10™ |

High reliability, zero-halogen, no-clean flux designed specifically for selective soldering applications and for prolonged heating processes on high thermal mass assemblies. 10% solids flux meant to be applied using a dropjet fluxer. |

| 2331-ZX |

Water-soluble general-purpose liquid flux with excellent solderability. |

| 2235 |

Water-soluble flux with relatively low 11% solids content and high activity. High ionic cleanliness without excessive foaming in standard water cleaning systems. |

| FLUXES: Solar |

| 952-S |

Zero-halogen, no-clean, non-rosin 2% solids flux for use in photovoltaic assembly equipment. Ideally for use with closed fluxing systems. Wide processing temperature window. |

| SF800-LR |

Zero-halogen, no-clean 1.5% solids flux for photovoltaic assembly. Low-residue formula with excellent solderability resulting in high peel force. |

| FLUXES: Water-Based |

| NF1060-VF |

Zero-halogen, no-clean VOC-free wave soldering flux. Excellent solderability and hole-fill. |

| 979VT |

No-clean, VOC-free wave soldering flux that produces excellent wetting and reduces micro solder balls. |

| FLUXES: Rework |

| RF550 |

High-reliability, zero-halogen, no-clean rework flux designed for electronic component rework and repair applications. Ideally used in hot air rework equipment. |

| TACKY SOLDERING FLUXES |

| Overview |

Kester tacky solder fluxes (TSFs) are the industrial standard for flip chip and BGA sphere attach. With viscosities optimized for high speed application and holding of a chip or sphere in place prior to reflow, Kester TSFs enable wide process windows for our users. Known for their active soldering, Kester TSFs ensure good electrical connections on known good die and components. |

| TSF-8818HF |

TSF-8818HF is a synthetic rosin-free, water-soluble tacky solder flux. TSF-8818HF is a zero-halogen formula that uses TSF-6852 best-in-class cleanable chemistry. TSF-8818HF works well in dipping, printing and dispensing applications. |

| TSF-6852 |

TSF-6852 is a synthetic rosin-free, water-soluble tacky solder flux. TSF-6852 has easy to clean liquid residues and solders quickly, allowing for short profiles. TSF-6522 is a rosin-based tacky solder flux that provides a wide process window for printing or dipping applications. |

| TSF-6522RH |

TSF-6522RH is a rosin-based, no-clean tacky soldering flux formula designed to be compliant with IEC 61249-2-21 definition for halogen-free materials. |

| TSF-6522 |

TSF-6522 is a rosin-based tacky solder flux that provides a wide process window for printing or dipping applications. |